Custom watch build #1: “Glass”

This was my first attempt at assembling my own watch from parts and I am calling it “Glass.” I have learned a lot through trial and error as I purchased cases, movements, movement holders, hands, straps, and tools. A simplified version of the process follows…

The details:

- Brand & Model: 10/6 Glass

- Diameter: 42mm

- Height: 11.1mm

- Movement: Hand-wound Sellita SW210-1

- Power Reserve: 42 hours

- Jewels: 19

- Lume: Bergeron Luminova

- Frequency: 28,800bph (4Hz)

- Crystal: Sapphire, Flat

- Water Resistance: 100m/300ft

- Strap: Torro Brava Italian Leather, Vintage Camel

Chinese mechanical movements are cheap and do a reasonable job of keeping time for the money. Though if you have a Chinese movement and Swiss movement side-by-side and interact with them much, the differences are blatantly obvious, from a machining standpoint. You know which one is better. More on that in another post (also coming soon).

I thought I would start with a cheap movement in a nice case, but such proved to be difficult. One, it is hard to find nice watch cases for purchase in small quantities. Two, cheap movements are not meant for nice cases. The monopoly in the watch industry is real.

So, for my first watch I ended up with a Swiss Sellita SW210-1 movement. It is an excellent hand wound movement, quite thin at 3.35mm, a great 42 hour power reserve, 19 jewels, and a 28,800 beat (4Hz).

But back to the beginning…the case. I started with a 42mm case from Otto Frei [http://www.ofrei.com]. Personally, I prefer any case between 38-42mm, with some exceptions. Ofrei has several options and reasonable prices for one-off or small-quantity orders. But it is the only place in the U.S.A that had what I was looking for in a case.

The case is meant to hold popular SW and ETA movements. However, I am trying the case with several movements given my own custom movement holders.

Dials are a main feature of a watch, but for my first foray I decided on something more open. No dial, let’s see what is under the hood. Some might call it a skeleton, I am calling this one “Glass.” Much like my [Minimal Wall Clock Project], hour markers are not essential for someone that is always looking at analog faces. The lack of a dial is both a design, cost saving, and experimental choice.

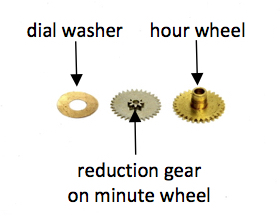

Yet, choosing to not use a dial has a drawback: how to keep pressure on the hour wheel so it stays on the central pinion and in contact with the reduction gear on the minute wheel. The minute hand will apply some pressure, but usually not enough to force constant contact. In other words, the hour wheel could easily lose contact with the gearing and result in incorrect time keeping.

In a watch with a dial, the hour wheel goes on the central pinion, then a dial washer is added on top of the hour wheel to add pressure as the dial sits on top of the washer, pressing against the hour wheel, ensuring the wheel stays in place and maintains contact with the reduction gear. In a skeleton watch, there are different solutions for applying the pressure when a dial is absent. Here is an example of an Akribos XXIV AK494SS. I have one of these, but be aware it is a cheap Chinese manufactured watch worth about $50 (don’t overpay for such things).

click on pictures to zoom

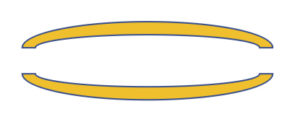

click on pictures to zoomWith the opposing dial washers and the minute hand, there is enough pressure to keep the hour wheel in place as the watch is worn. So, I secured the movement to the movement holder (comes with case) using the screws (comes with movement) and then assembled the hour wheel, washers, and minute hand.

Attaching watch hands is tedious, but entertaining in my opinion, and requires the right tools. Most important is some sort of magnification. Good tweezers help, Rodico is better. Patience is a must. A watch hand press is not hard to find and purchase, but you have to find attachments that match the hand diameters you are using. Again, the watch world is that of a monopoly. It can be hard to find a press and attachments that match the variety of movements and hands you want to interact with, but there are cheaper and more readily available options.

Another issue was that of the crown stem. I ordered a 20mm long stem when I purchased the movement since the case was 42mm. The stem that comes attached to the movement (16mm) is not long enough for the case, so you have to buy a longer stem and cut it to size.

Place the gasket, set the tension spring, and screw on the case-back. Again, the right tool helps, in this situation a 3-prong watch case tool.

Hi, thanks for this. I also make up my own watches, and ‘sign’ the dials using water slip transfers designed for model train sets (look up fox transfers). I am getting fed up with Rolex and other copy cases, so that Otto Frei one looks great, I will get one for my ‘Triton watch’. This will be a totally custom dial with SuperLuminova and GTLS bulbs for hour indices AND hands. Its fiddly but you CAN set the bulbs in the face and hands, to give a glow all night result.

Keep up the experimentation!!

Padd

Cool, and thanks! I plan to experiment with the waterslide decals myself in the months ahead. I have the printer and setup ready to go, just need the time to do all the testing and recording for the site/channel 🙂